Visual Rating of Ten Common Color Fastnesses

一、Requirements for visual rating of color fastness

Environmental requirements

During rating, the required background should be neutral gray (between level 1 and level 2 of the color-changing gray card). In order to avoid the influence of external light, our rating must be carried out in a dark room. At the same time, no other debris can be placed in the light source box.

2. Personnel requirements

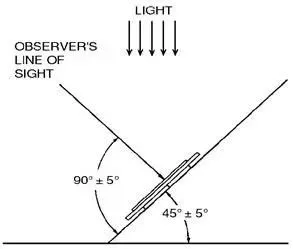

The rater cannot be color blind or color weak, cannot wear colored glasses, and the rater should wear neutral gray work clothes. During rating, the incident light of the light source box is about 45° at an angle to the textile surface, and the rater's observation direction is roughly perpendicular to the textile surface.

3. Equipment requirements

The lighting conditions of the light box should be sunny daylight (9:00-15:00), or an equivalent light source with an illuminance of 600lx or above. When rating, the discoloration gray sample card used must comply with GB/T 250-2008, and the staining gray sample card must comply with GB/T 251-2008. The color of the cover plate for the original sample and the sample after the test should be consistent, preferably neutral color or gray or black, and the size and shape should be roughly the same.

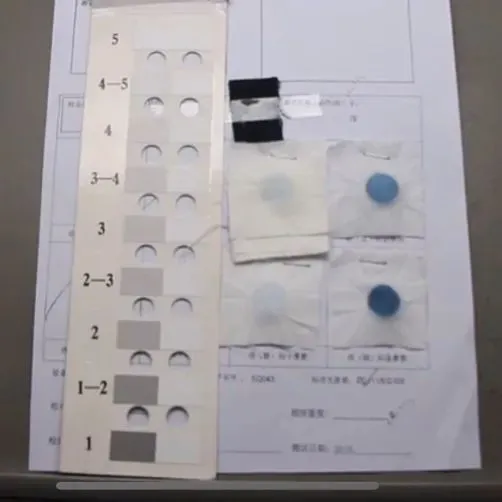

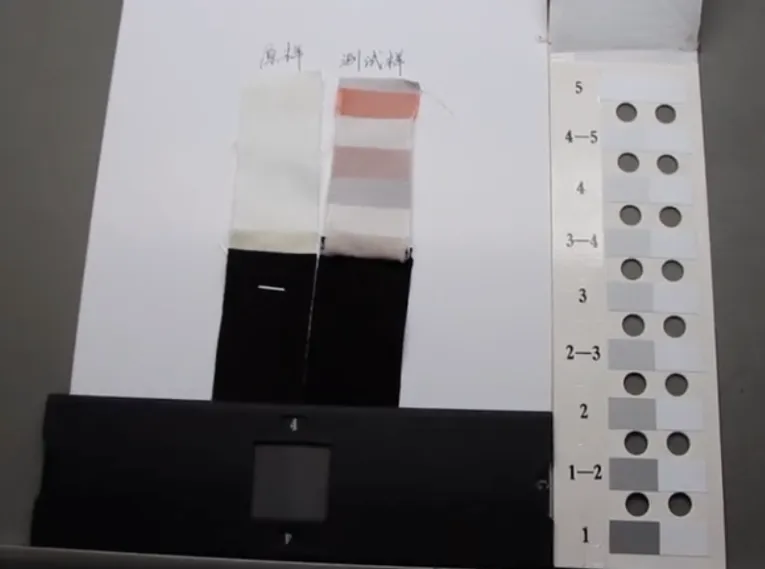

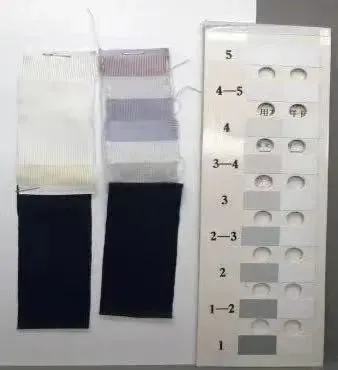

Visual rating is based on the gray sample card (discoloration gray card or staining gray card), which is divided into five levels and nine grades. Level one is the most serious fading, and level five is no fading. Next, the rating summary of various tests for color fastness is introduced.

二、 Rating of 10 Common Color Fastness

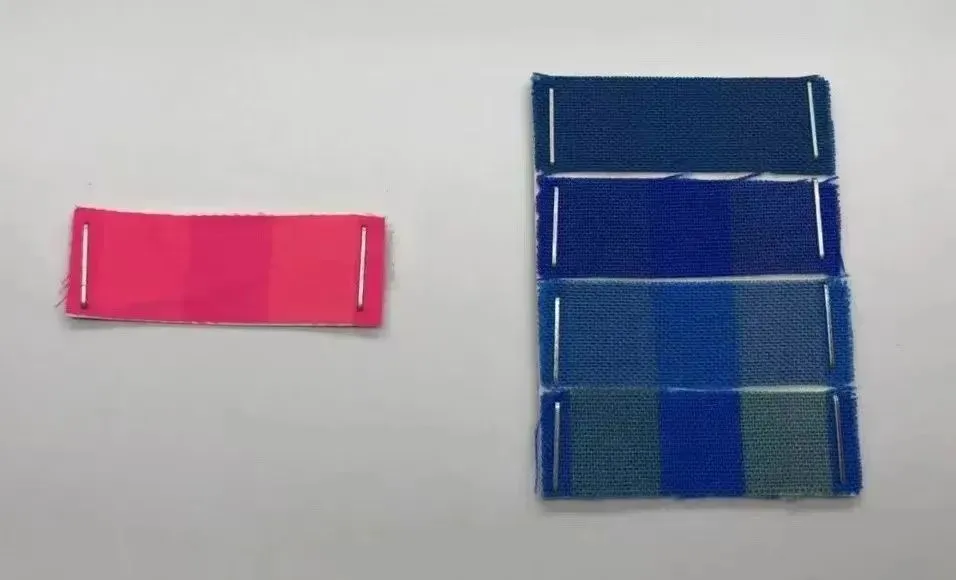

- Color fastness to friction

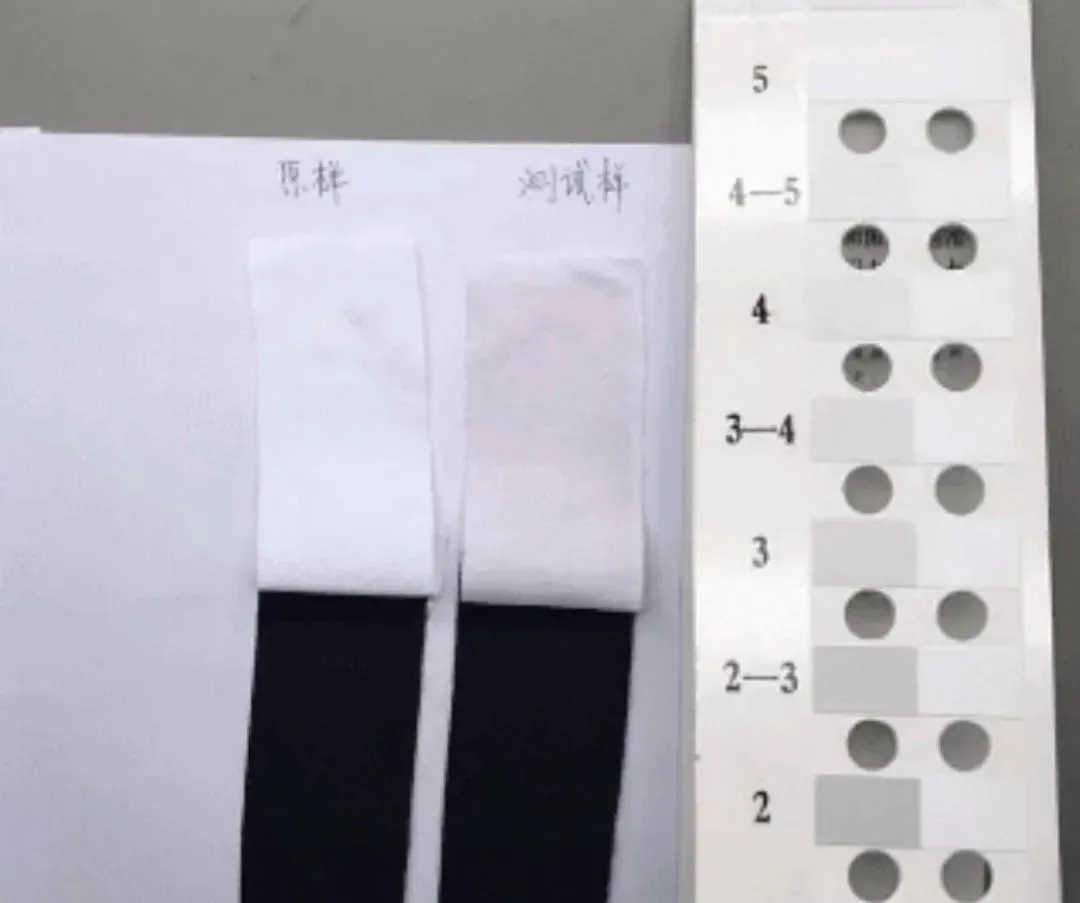

In the friction test rating, wait until the cotton cloth for wet friction test is completely dry, remove the excess fibers on the cotton cloth that may affect the rating, then place three layers of cotton cloth on the back of each friction cloth being rated, and finally use the gray sample card for evaluating color staining to evaluate its color staining degree.

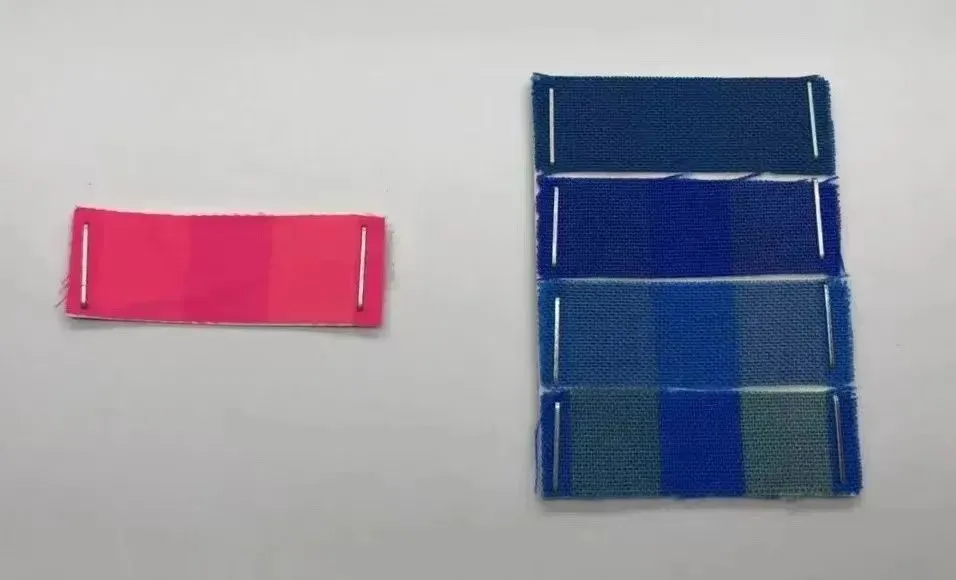

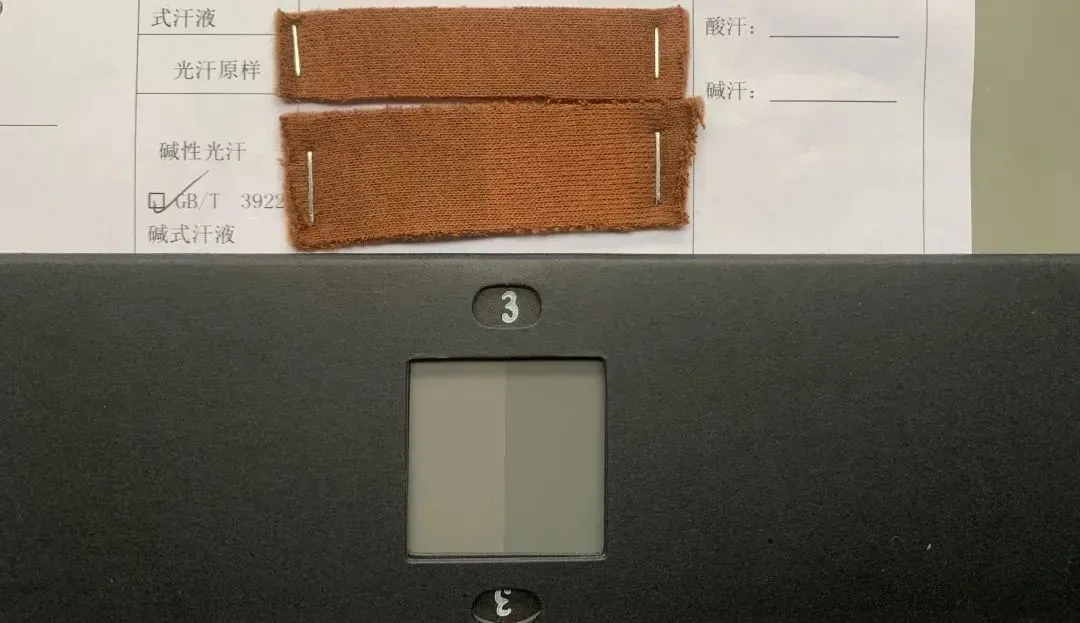

2. Color fastness to soap washing, water, sweat, saliva, seawater, etc.

For the rating of these color fastness tests, they all use an original sample and an untested adjacent fabric as reference samples, and then evaluate the color change of the sample and the staining of the adjacent fabric.

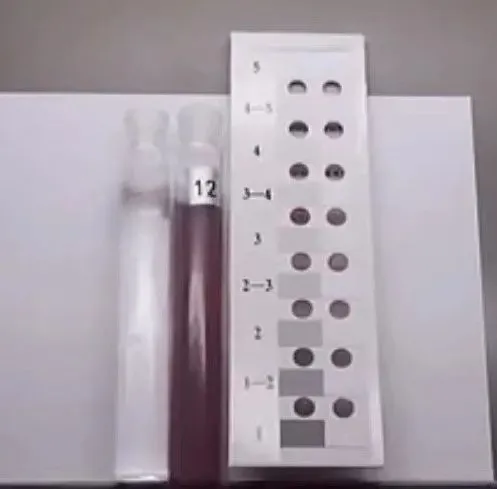

3. Staining of washing liquid

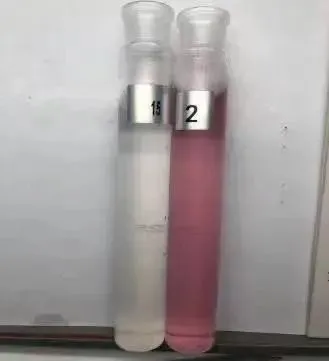

For the rating of staining of washing liquid after soap washing test (refer to FZ/T 73020-2019), the rating should be completed within 15 minutes after the test. After removing impurities from the soap liquid, pour it into a colorimetric tube, use the unwashed soap liquid with the same test temperature as the reference sample, and use the staining gray card to evaluate the staining degree of the washing liquid under D65 light source and white cardboard as the background.

4. Color fastness to light

Taking GB/T 8427-2019 method 3 as an example, in the rating of the light fastness test, a sample and a target blue wool standard sample and a blue wool standard sample one level and two levels lower than the target blue wool standard sample are exposed together until the end of the exposure, and then the exposed sample and the blue wool standard sample are compared for grade determination. During the evaluation, each stage of the sample corresponds to the blue wool standard sample. If the grades obtained at different stages are different, the arithmetic average of the grades at different stages can be used to evaluate the grade; when the average color fastness to light is not a whole level or half level, the nearest higher half level or whole level is taken. (The American standard is to evaluate the sample after sun exposure and the original sample according to the color change gray card)

5. Composite color fastness to light and sweat

Taking GB/T 14576-2009 as an example, expose the sample together with the blue wool standard sample until the end of the exposure. After the test, wash and dry the sample, and then evaluate it with the color change gray card.

6. Color fastness to hot pressing

For the rating of color fastness to hot pressing, immediately after the test, the color change of the sample should be rated using the color change gray card, and then the sample should be placed in a standard atmosphere for 4 hours to adjust the humidity, and then the color change of the sample and the staining of the cotton adjacent fabric should be evaluated. When evaluating the staining, the side of the cotton adjacent fabric with heavier staining should be evaluated.

7. Splicing color fastness

After the test of this item is completed, the sample should be rinsed to clean the residual detergent on the sample. After the sample is dry, the gray sample card for color staining is used to evaluate the staining of light-colored fabrics.

8. Color fastness to dry cleaning

The current standards for dry cleaning color fastness tests are divided into the new version GB/T 5711-2015 and the old version GB/T 5711-1997. Old version: After the test, filter the solvent left in the container with filter paper, then pour it into a colorimetric tube, use transmitted light, use the staining gray card to evaluate its staining, and finally use the color change gray card to evaluate the color change of the sample. New version: Use an original sample and an untested adjacent fabric as reference samples, and then evaluate the color change of the sample and the staining of the adjacent fabric.

GB/T 5711-1997

GB/T 5711-1997

GB/T 5711-2015

GB/T 5711-2015

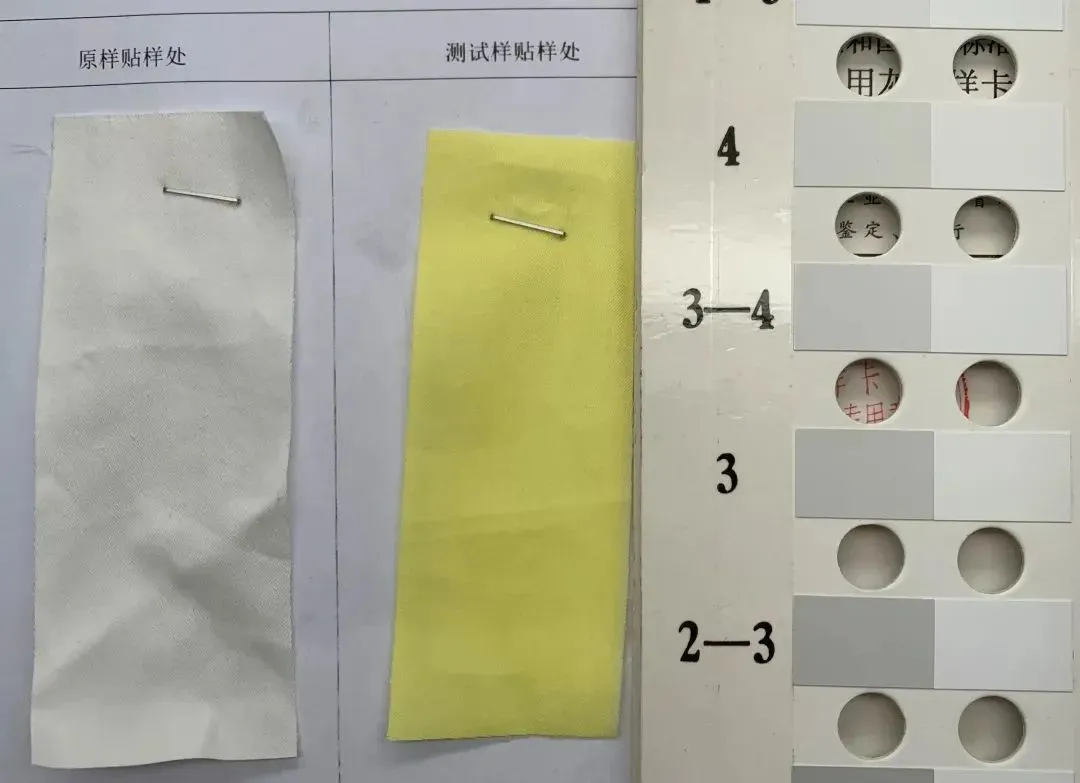

9. Evaluation of potential phenolic yellowing (yellowing resistance)

After the test, take out the test package and cool it down. The evaluation of each sample must be completed within 30 minutes after opening the test package. When rating, first use the staining gray card to evaluate the yellowing degree of the controlled fabric. If the yellowing degree is equal to or less than level 3, the test is valid, otherwise it is invalid. If it is valid, then use the staining gray card to evaluate the yellowing degree of the sample.

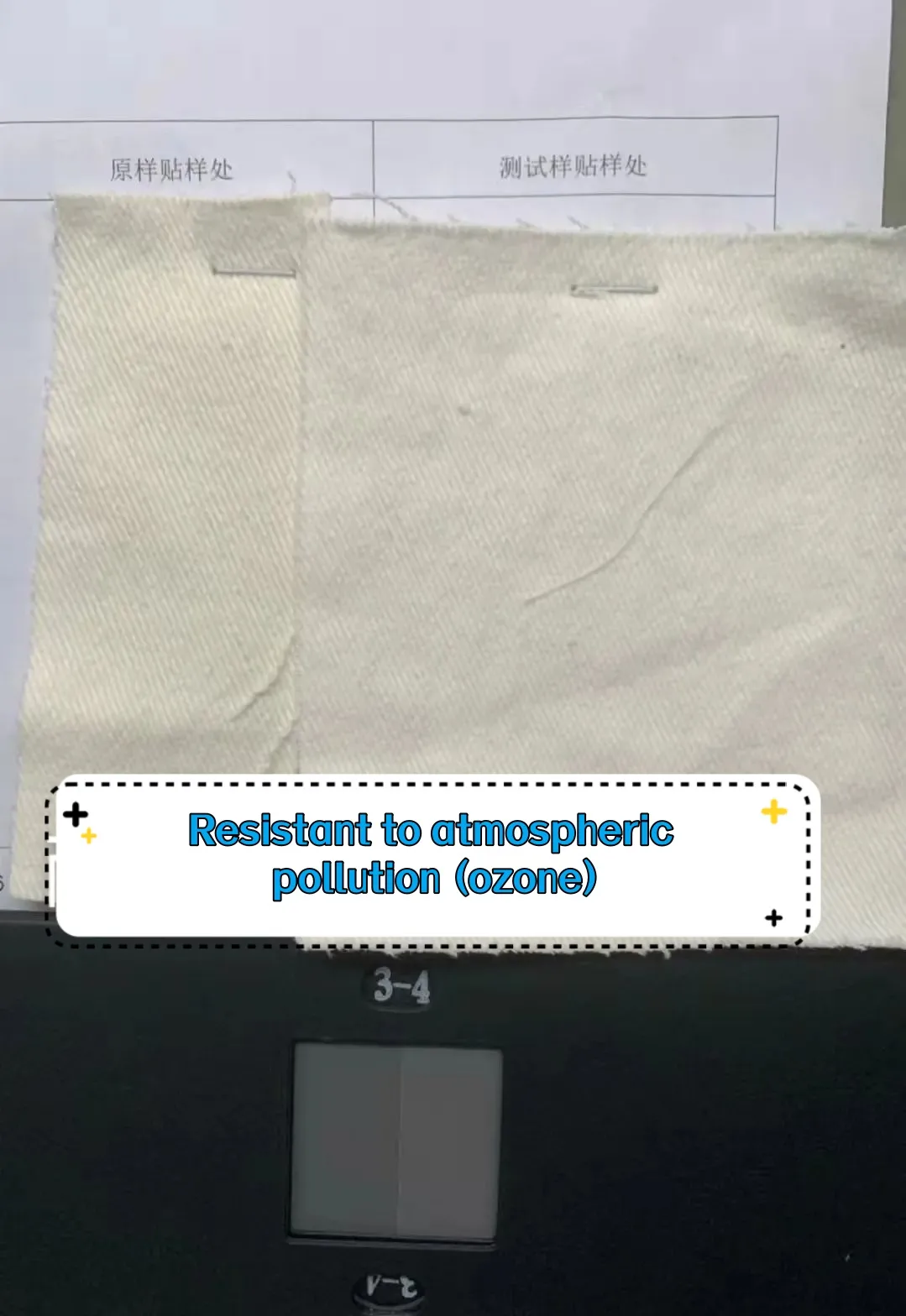

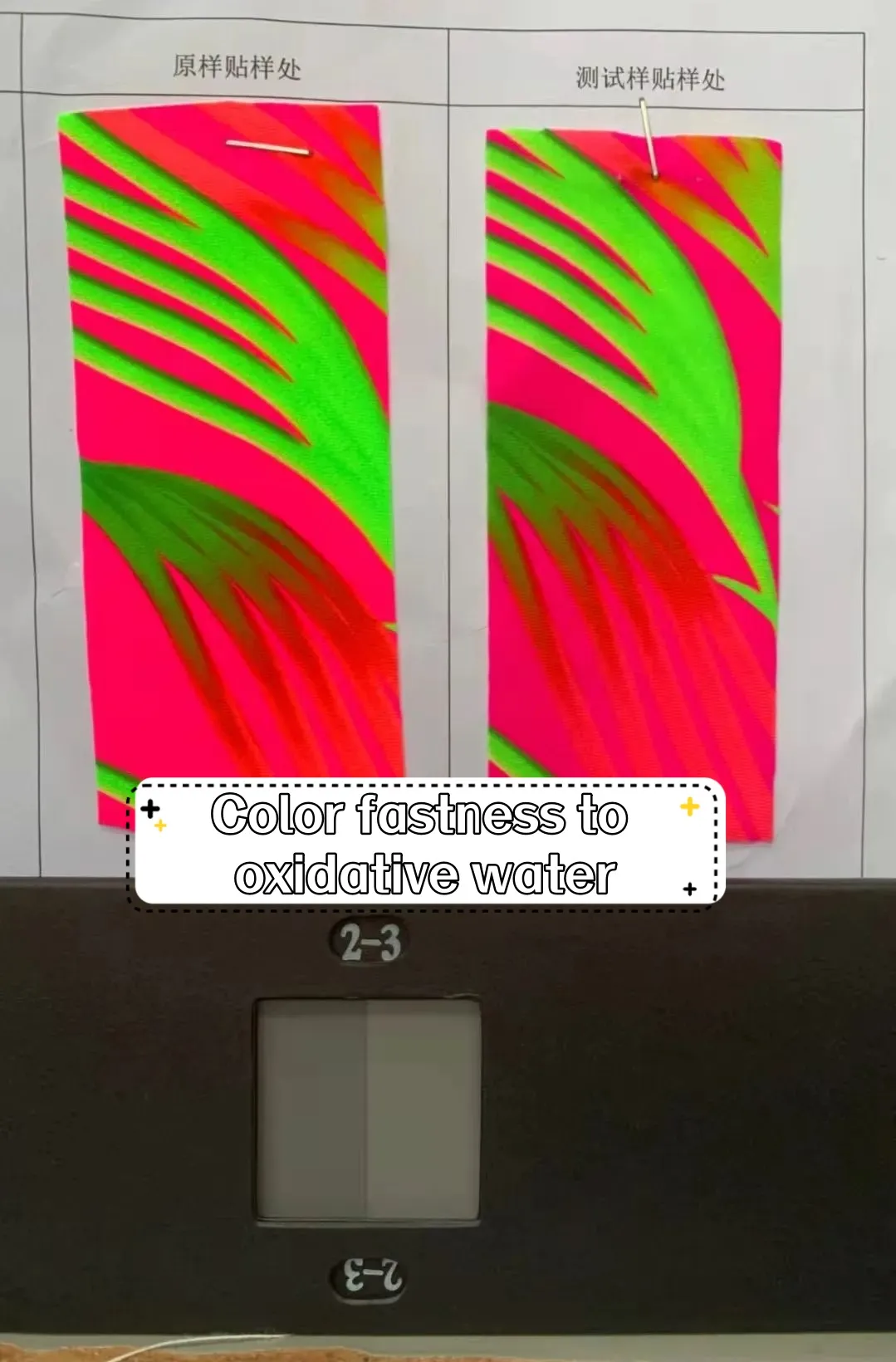

10. Color fastness to chlorinated water, atmospheric pollutants (ozone), and hypochlorite bleaching

After the test, use the color change gray card to evaluate the color change of the sample.

In summary, there are three main ways of rating:

① Color change rating, the sample after the test is evaluated according to the color change gray card;

② Color staining rating, the light-colored sample, lining or solution after the test is evaluated according to the color staining gray card with the original sample (blank lining, original solution);

③ Lightfastness rating, taking the national standard method 3 as an example, the color change degree of the sample after sun exposure is compared with the color change degree of the blue wool standard sample. The American standard is to evaluate the sample after sun exposure and the original sample according to the color change gray card.

Rating work is a display of the results of color fastness testing and is the last step of color fastness testing. No matter how accurate and standardized the previous process is, if there is an error in the rating, all the efforts of the former will be wasted. The consistency of vision is particularly important. In a small range, it is necessary to ensure the consistency of vision of each person in the laboratory, and in a large range, it is also necessary to ensure the consistency of vision between various testing institutions. Only through continuous comparison of personnel and comparison between institutions can the stability of color fastness rating be guaranteed at all times.

-

Versatile Usage & Applications for Modern Textiles:Poly Cotton FabricNewsJul.07,2025

-

Types of T-Shirt Fabrics: A Comprehensive Guide for WholesalersNewsJul.07,2025

-

The Versatility of Light Grey Fabric in Fashion & ApparelNewsJul.07,2025

-

The Versatile World of Fabrics: Kala Cotton Fabric & MoreNewsJul.07,2025

-

Poly Spandex Fabric: The Ultimate Guide for Wholesale BuyersNewsJul.07,2025

-

Fabric Medicine: Healthcare Upholstery's RoleNewsJul.07,2025

-

Hebei Niuyuan Technology Co., Ltd.: Your Trusted Partner in Sustainable Textile MaterialsNewsJun.27,2025